Spray Booth PLC Control System

Project Details

ClientQuartzTec

SectorSemi-Conductor Glass Annealing

Services UsedSiemens Logo PLC

Our client in East Kilbride had built a bespoke spray booth to clean off semi-conductor parts prior to the next step in their process.

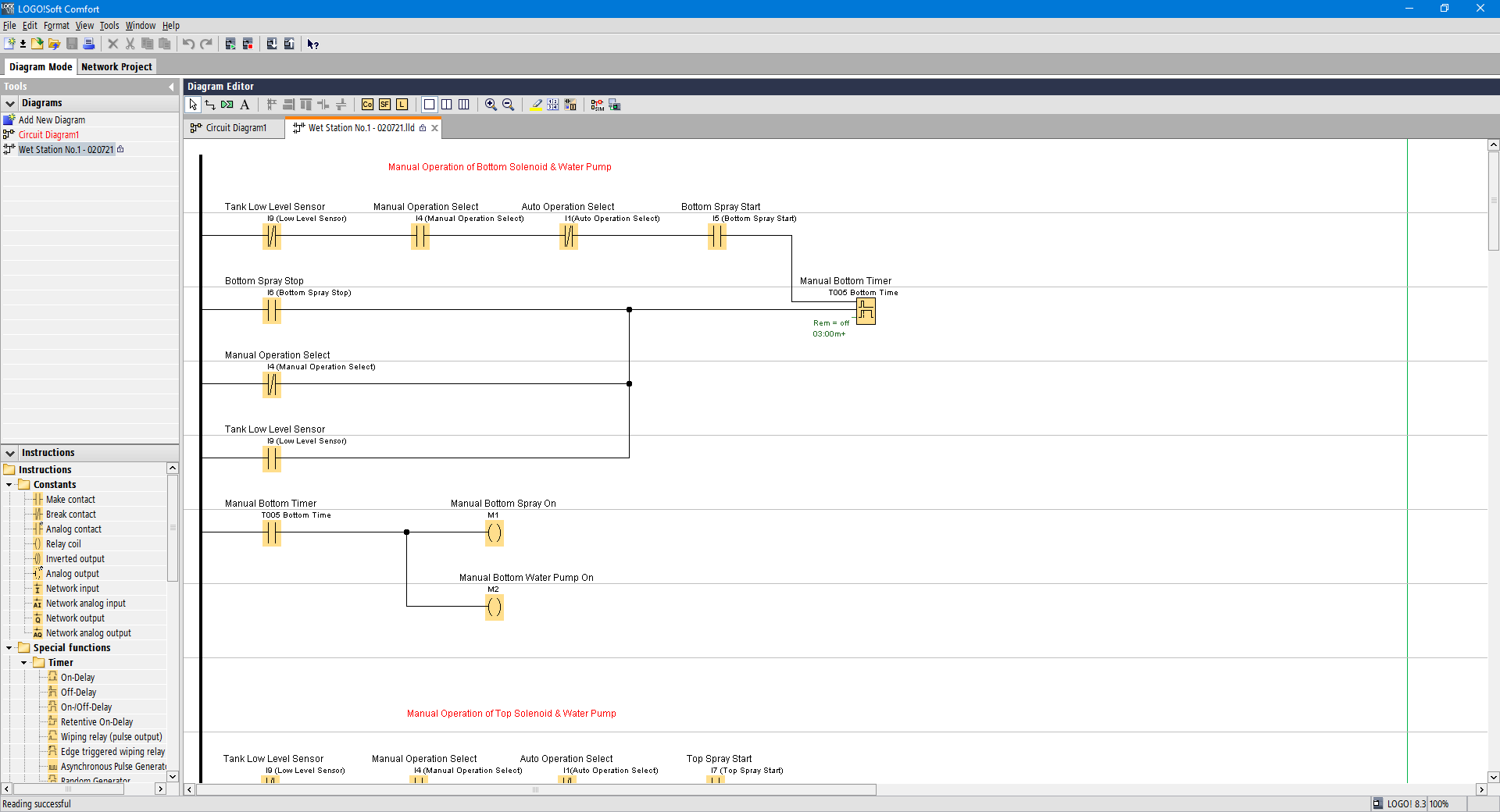

We were contacted to provide a fairly low-cost technical solution that would control the operation of the spray booth including stop / start / manual / auto functionality and the ability to control the operation of the top and bottom sprays as well as controlling the water tank level on the booth

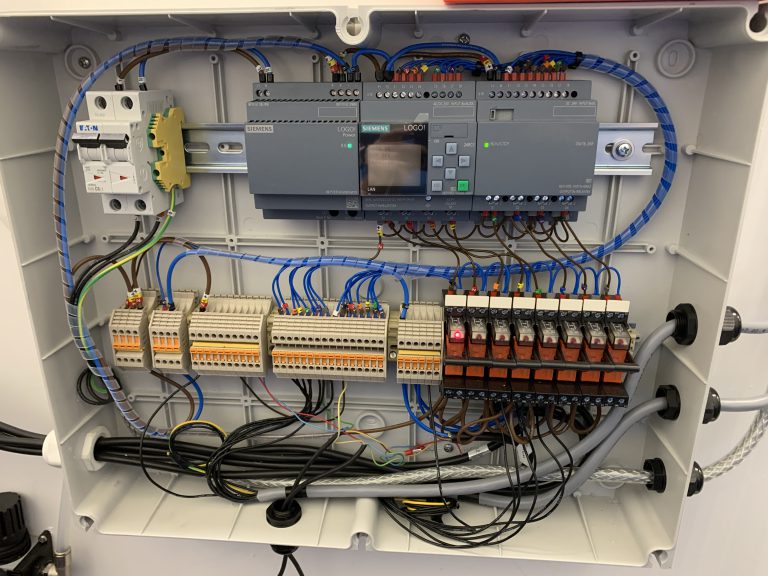

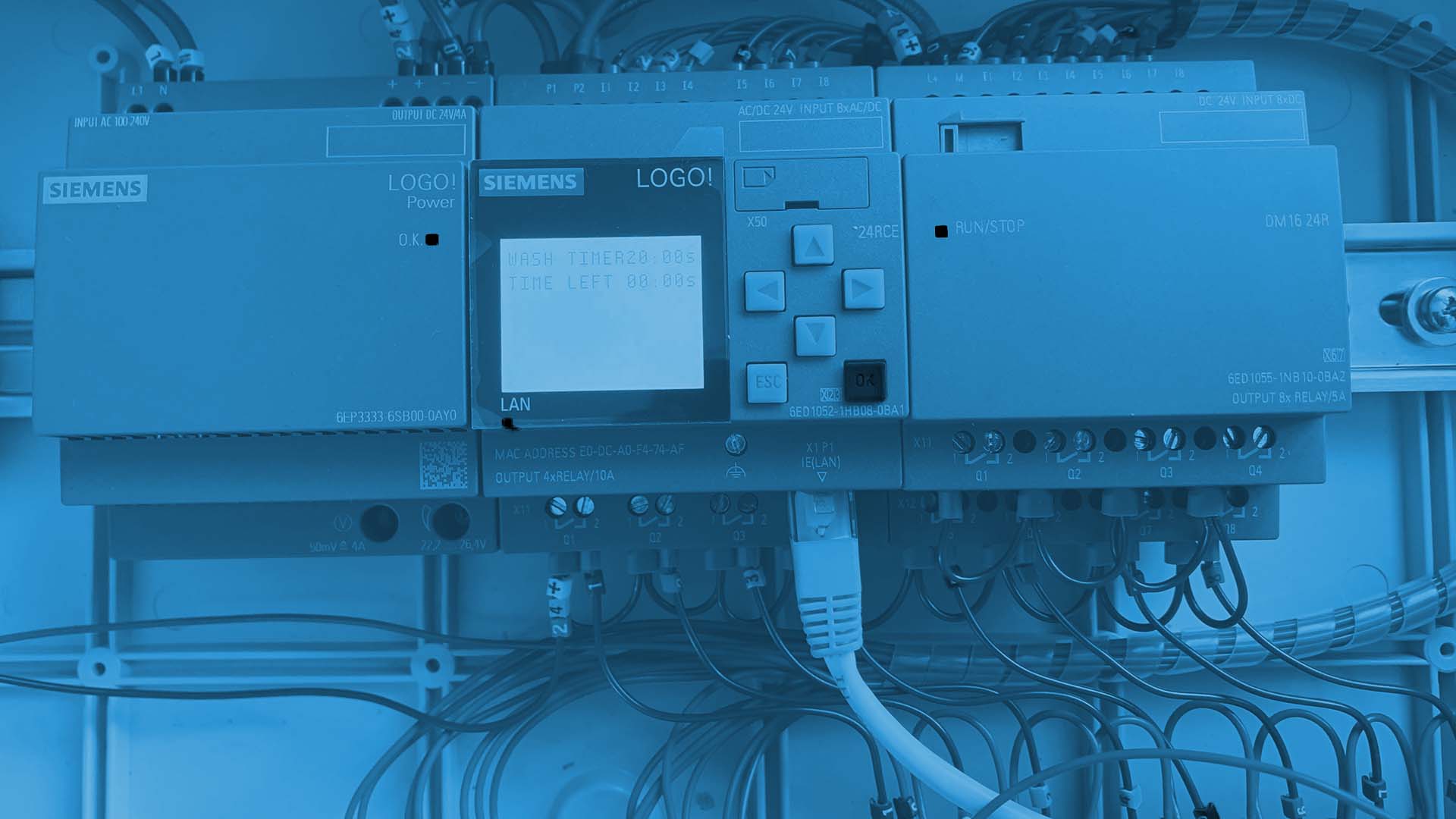

We worked with the site Maintenance Manager to determine his technical requirements before proposing a solution utilizing a Siemens Logo PLC with Digital Input and Digital Output functionality to turn on / off water pumps, spray solenoids, etc. via internal timers and interlocked with safety features such as emergency stops and door open / close switches.

The control system included the following:

- Siemens Logo PLC with ModbusTCP capability for potential connection to SCADA system.

- Web Server capability.