Temperature Uniformity Survey (TUS)

A TUS is performed to validate the temperature uniformity characteristics of the qualified work zones and operating temperature ranges of furnaces or ovens.

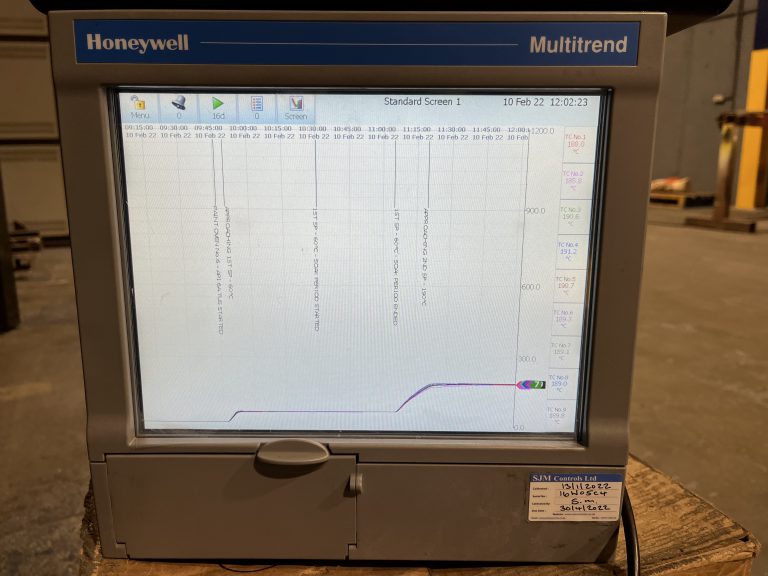

The TUS validates the temperature characteristics of the work zone and should closely match a typical heat-treat cycle with respect to ramp up speed and temperature setpoints.

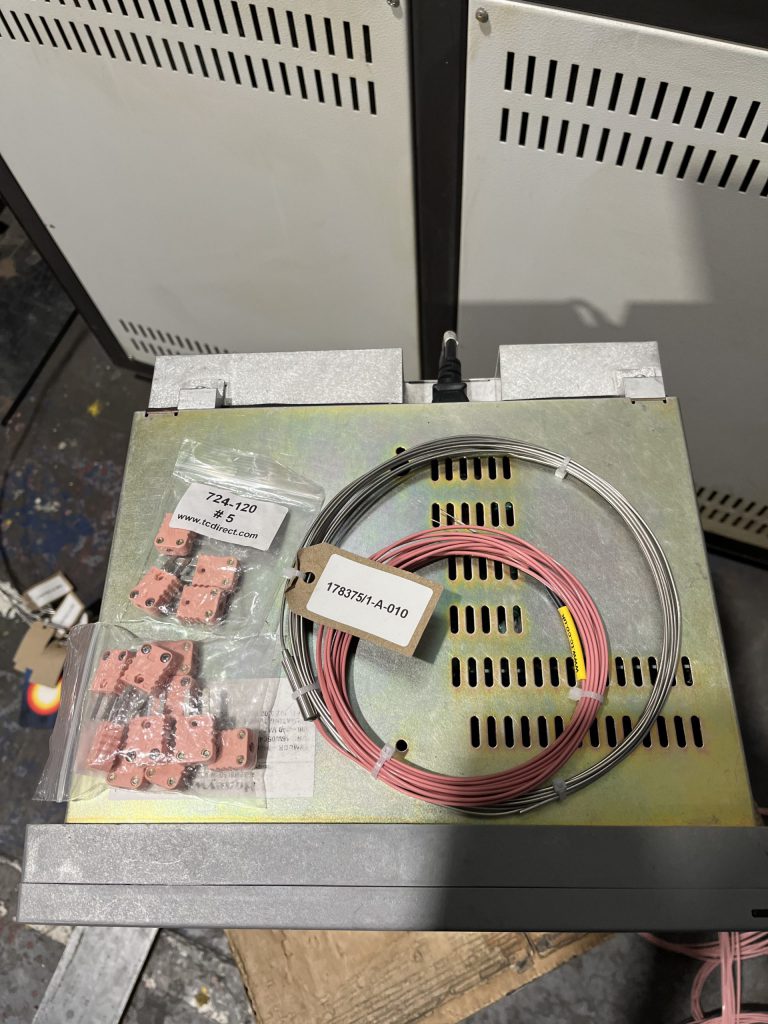

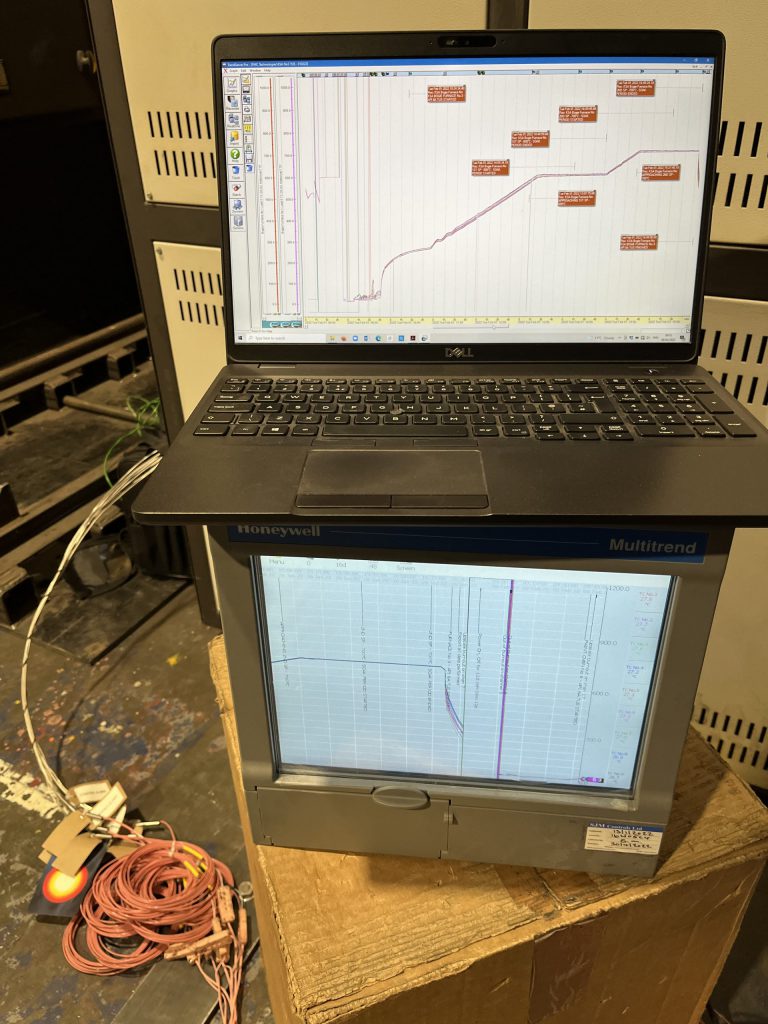

SJM Controls Ltd will perform TUS’s to comply with the requirements of industry standards such as AMS2750 Rev G and API 6A using suitably calibrated thermocouples and paperless data recording devices.

A comprehensive TUS report will be generated on completion which will detail the temperature readings throughout the furnace and highlight any potential “hot” or “cold” spots within the working area of the furnace to cover the minimum and maximum working temperatures used in production.

Our engineers have great experience in this work within industries such as aerospace & automotive and we can also perform System Accuracy Tests (SAT’s) as part of AMS2750 Rev G requirements.

Other forms of temperature monitoring can also be performed on Key Production Rooms, Cold Storage Rooms, Drying Kilns using conventional thermocouples and data recording devices as well as wireless solutions.

Industrial

applications

AMS2750 Rev G

Instrumentation calibration, Temperature Uniformity Surveys and System Accuracy Tests to full compliance of latest revision of AMS2750 Rev G.

API 6A

Instrumentation calibration and Temperature Uniformity Surveys full compliance to API 6A.

Environmental Room Monitoring

Pharmaceutical Production Rooms, Food Cold Storage Areas, Drying Kilns etc. can all be mapped for temperature and / or humidity with the use of sensors and data recording devices.

Wireless Room Monitoring

Wireless temperature and humidity sensors can be used for room mapping for a less intrusive solution.